Maintenance of steel piles for a toll bridge in Virginia

Petroleum pier piles are strengthened with the SeaShield FX-70 System

Railroad trestle timber piles are repaired and protected by SeaShield FX-70

A full-length square SeaShield FX-70 interlocking jacket is easily opened by one man for positioning around a pile

SeaShield FX-70 System applied to Offshore Oil Platform in the Gulf of Mexico

Jackets were fabricated in two-foot sections and ranged in diameter from 18 inches to 33 inches

Application of the SeaShield FX-70™ System

SeaShield FX-70 applied in difficult conditions

The SeaShield FX-70 System provides corrosion protection to the splash zone area of the steel pile

Pipe lengths wrapped with the Premier Butyl Tape System

Pipe lengths wrapped with the Premier Butyl Tape System

Premier Butyl Tape System

Pipe lengths wrapped with the Premier Butyl Tape System

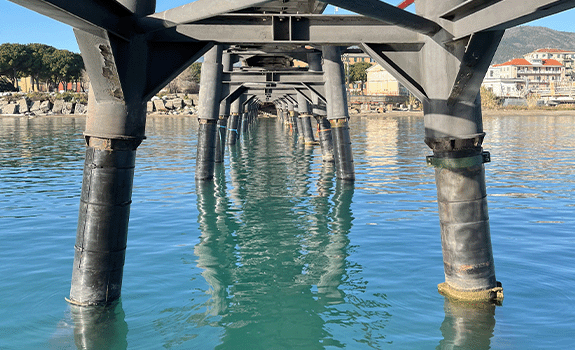

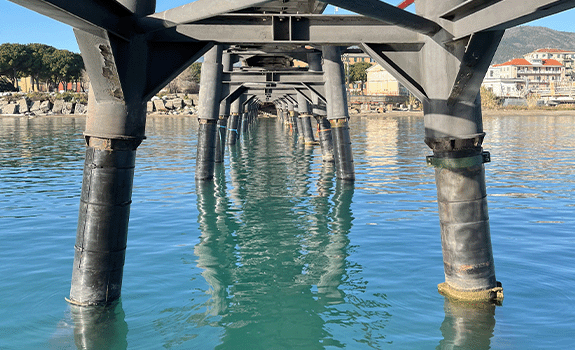

The ESSO Italiana S.r.l. jetty.

Prempaste S105 is applied to the top of the pile (L) followed by profiling with Premier Moulding Compound (R).

SeaShield Marine Piling Tape was applied in vertical sections first, then circumferentially around the pile.

Application of the Premier™ GOW UV.

The completed system application (L) and the trial upon revisiting 4 months later (R).

After loose material, dirt and debris is cleaned from the application area, Premtape Hi-Tack Primer is applied

Premtape Hi-Tack Tape is applied to wind turbine base

Premtape Hi-Tack is applied to the base of the wind turbine

Premier Ultraseal RT Tape is applied to the base of the wind turbine

Paddleworth reservoir new build project

Paddleworth reservoir new build project

Paddleworth reservoir new build project